Sussex Sash window Restoration Ltd is the only company that can restore your sash windows using the same method in which they were made originally.

We only use traditional methods to re-construct casement and concealed box sash windows back to how they were when they were first made.

We come across many windows that people have tried to restore. Some things that some carpenters or companies have done or used to try and restore the sash windows is shocking. This can cause you serious problems in the future with people thinking that they are helping. One of the things we encounter is foreign objects in the sashes and frames. The main culprit is screws and nails that people have installed in the sashes. Whether this is in the sash or the box frame it causes ROT, no question about this.

One of the bad suituations that you can come accross is Dry and wet rot. this is basically a cancer of woods and must be removed at all costs. this fungus takes all the goodness from the timber and the wood will start to fold in on itself. The pictures below show a 300yr old casement window ravaged by Dry rot at Windlesham House.

When windows are constructed you don’t use screws or nails, they use wooden dowels in the tenons. This makes the window very strong as you have the grain of the timber going in 3 different directions. the only exception should be if you are extending the window cills to create a sub-sill. This should always be done with stainless steel This should be plugged to create the seal over the screw. Filler should never be used because the dowel also moves and shrinks at the same rate as the wood you have installed. .

How to restore sash windows to an English heritage standard

The sashes are evaluated before on the first survey, so we take all the measurements and the dimensions of the product.

We would then make sure that all the timber was in stock and of very good quality. The timber is always handpicked from the sawmill by one of our employees and not delivered. This way we can always look for a nice straight nice grain like you would see on Southern yellow pine with no defects and nots.

When we work on the sashes or doors, we always take them back to the workshop. This happens so we can take all the paint of the product to see how far the rot has gone. We mainly look at the colour of the wood which should be a beautiful grey if no paint is present. If it is black, then this is a sign that rot is has penetrated quite deep and the surface could be dry. Brown means that it is at the surface of the wood and it could be saturated.

If the joints have opened up, then we would look at stripping the window apart by firstly taking out the glass and burning of all the paint. If you are burning of the paint this should be done with the right ppe, extractors and insurance.

We would then strip the window apart and see what parts are okay if they are okay then we would re-cramp the sashes back together again and dowel them so no more movement occurs. then we would reglaze the window with the original glass if applicable

If the sashes are rotten what happens then.

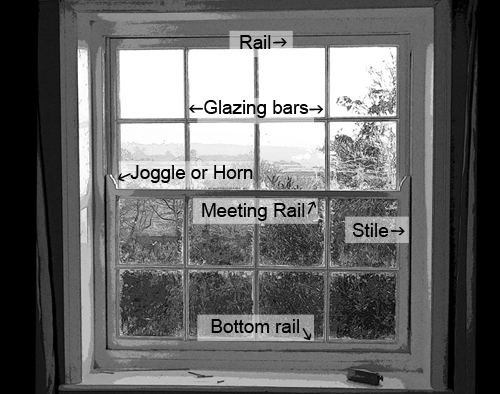

Well if the windows are rotten and they are listed then you must restore them no matter what. With listed properties planning permission should be applied for if any replacement is done. When we get the windows and there is rot present in the bottom rail, stile or meeting rail. We would look at manufacturing a part for the sashes or doors. Windows and doors are all constructed the same way but doors can be much bigger. They are put together with tenons and mortices on the rails and stiles and machines are used to manufacture these components.

The machines that we use are thicknesser, 3 headed tenoner, Morticer and a spindle moulder just to make each part.

Window Construction through time

You can tell when the windows are new as the measurements are usually 45mm, 53mm and 58mm to cater for double glazing. Original sashes would be 35, 38, 40, 42, 47 and 53mm depending on the area.

This would always have crown or cylinder glass installed in them, so they did not need to be that thick. When they are of the first 3 sizes then they would normally be an Ogee moulding on the profile. The bigger ones are more Regency and could have a Roman Ogee or lambs’ tongue as the mould. These are usually bigger windows and would normally have thicker glass.

The calculations are the same when constructing a window and that is a rule of thumb of third, third, third. This means that the tenon and mortice would be a third or 10-12mm and 15mm for the bigger windows. So, if you have a 35mm window then the ogee mould would calculate at 6-8mm. Then it is just the height of the mould that must be looked at and is usually 5- 6.5mm. so to restore a window properly to the exact detail you would need a profile cutting machine. These are all machines that we have put together in the workshop to create an easy working environment.

So our methods are different from other companies and we try not to use the Dry-flex woodcare system in masses. We produce new parts for the windows and doors which conforms with all listed building legislation..

Restoring the casements without replacing the Stile.

There is one other way that you can restore a sash when it is listed that we use. The City and Guilds Site Carpentry and Architectural Joinery for the Level 3 were very interested in this technique. They have now included this on the new september course publication with one of our projects as an example.

The way that you join 2 pieces of timber/ stiles together is called a scarfe joint and resembles a Z . This makes the timber solid and forces the pressure in every direction across the wood. This is then glued with PU glue and dowelled. It will create a full length of timber which is then run down the spindle moulder and a mortice installed.

Considering this casement sash window had dry rot we managed to save 50% of the original sash, frame and glass. This keeping to listed building standards and restoring the window